With the help of MVLW (My Very Lovely Wife) the centreboard was manoeuvred into position for a test fit.

It immediately became apparent that the pivot pin did not fit - it refused go through the hole in the centreboard.

A quick check with a square revealed that the pivot holes in the keel were not perpendicular, vertically or horizontally! I had drilled them by eye, so it was not entirely surprising.

I filled the holes with resin and re-drilled them with the drill guide clamped to the keel to ensure that the holes were properly aligned.

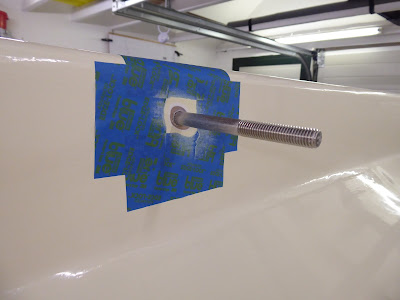

Here is an M10 bolt passed through the keel to check it was true.

It was, so I refitted the pendant ready for installation. Here the tied and heat sealed knot sits snugly in its hole in the board. The pendant is 6mm Dyneema.

The board was reinstalled and the pivot pin was test fitted, as here.

The holes were lined up and true, but it was clear that the hole in the board itself needed to be reamed out a fraction for a good fit.

The board was then raised up and the hole enlarged very slightly in situ with a rasp, like this.

The pivot pin was then successfully fitted, like this.

And lastly the pin was sealed in place with thickened epoxy resin, as here.

The resin was held in place with tape while it cured.

That was a lot of drama, but all is well that ends well!